Traffic Sign Language

22nd Jun 2022

Substrates, Sheeting for Signs and Retroreflectivity

Substrate - the basic material used to construct the sign. Usually .080 aluminum or 5/8” plywood.

Annodize or Alodine Aluminum – Is the protective coating on the aluminum allow you to paint and/or put reflective sheeting on your signs. Untreated aluminum is too greasy and dirty and the paint or sheeting won’t adhere to it. This is a seven step process of dipping the aluminum in tanks of chemicals and rinsing them.

Sheeting – The material the sign face goes onto is the substrate.. It is the sheeting that determines the level of retroreflectivity and the durability of the sign. Traffic signs are required to be reflective by the Manual on Uniform Traffic Control Devices (MUTCD).

Retroreflectivity – Is a measurement of how much light, from car headlights is reflected back to the vehicle. There are several different types of reflective material that have different levels of luminosity and durability against peeling, fading or cracking.

Types of Substrate and Their Uses

There are three industry sizes: .063 for signs 1.5 square feet or less, .080 for signs less than 12 square feet and .125 for signs greater than 12 square feet.

½” and 5/8” plywood are also used for signs. Usually sign 9 square feet and larger are made from High Density Overlay Plywood. Temporary construction sign us MDO – Medium Density Overlay Plywood.

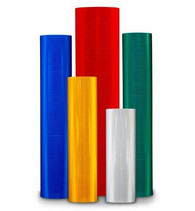

Types of Sheeting

Engineer Grade Retroreflective Sheeting

The most basic type of retroreflective sheeting is Engineer Grade (EG), which is also referred to as Type I. EG is made up of small glass beads, which are either enclosed in a translucent pigmented substrate or two layers of prismatic sheeting. Engineer Grade retroreflective sheeting doesn’t have a distinctive pattern. It is recommended for commercial and non-critical traffic sign applications.

When EG sheeting is applied properly, it can be expected to deliver retroreflection for five to seven years. Road signs with EG sheeting are visible from 400 to 600 feet away.

High Intensity Prismatic Retroreflective Sheeting

High Intensity Prismatic (HIP) retroreflective sheeting is also referred to as ‘encapsulated lens’ sheeting. It consists of two layers: an outer translucent pigmented layer and an inner reflective layer with glass beads. The two layers are connected by a ‘lattice,’ which gives the sheeting its distinctive honeycomb appearance.

HIP sheeting is made up of prismatic cells. When a light beam lands on a sign with HIP sheeting, the light hits the sides of the prismatic cells and reflects back at a wider angle than it came. This means more light is reflected back towards the source of the light.

This type of sheeting is typically used for highway signs and when applied properly can last up to 12 years. Visibility of signs with HIP sheeting is from 800 to 1,200 feet away.